Case study

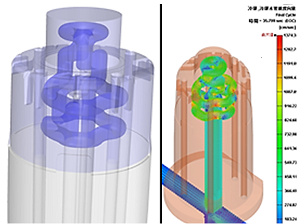

Mold industry

By incorporating the advantages of advanced software analysis and additive manufacturing, GC Precision provides complete mold design & manufacturing with “conformal cooling channel”, offering the soundest solutions to the requirements of high-precision and extended-service molds of plastic injection/metal die casting!

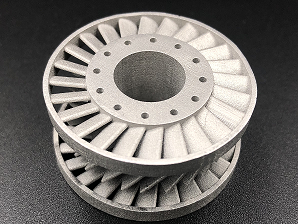

Aerospace industry

GC Precision, in collaboration with academia, and using design optimization and metal additive manufacturing, is able to make parts light-weighted while achieving high performance, effectively reducing the cost of rocket launching.

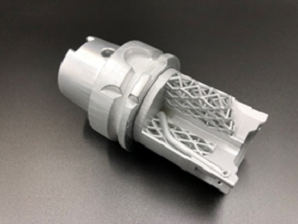

Thermal conduction

Application of the features of metal additive manufacturing enables making structure design with high thermal dissipation, maximum thermal conductive areas and compact volume.

Tools

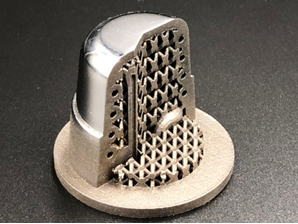

The combination of metal additive manufacturing and CNC lathe-milling machines enables custom making of high-performance (high speed/high cooling effect/high efficiency) machining tools that meet customers’ machining requirements.

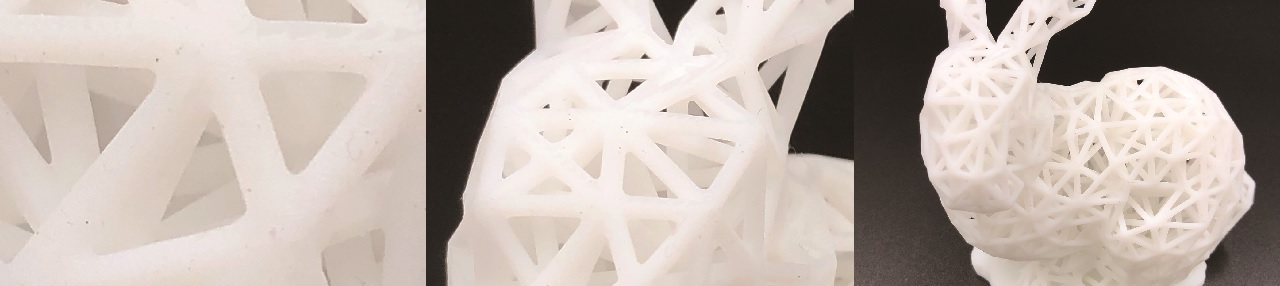

Other parts/products

Out of the box of traditional processes that can deal with the “appearance” of workpiece only, metal additive manufacturing is capable of producing parts to correspond to special requirements (e.g., light weight and changes in structural strength). Coupled with lattice design, for example, it gives the manufactured products the features of both light weight and high strength, whereby to provide breakthrough solution in the applications like aerospace, racing or high-speed mechanisms that require exceptional weight/strength ratio.

Precision & miniaturization parts

As the technology go forward , more and more products are toward to high precision & miniaturization. Thus it is difficult to make these kinds of parts in traditional progress(CNC machining, grinding……), but now we can achieve the requirements by AM progress.