Case study

Mold industry

For plastic injection or metal die casting, molds are normally a decisive factor of quality, particular in the finished products that require complex shapes and high precision.

Combining advanced software analysis and the edge of additive manufacturing, GC Precision offers comprehensive design and manufacturing of molds with ‘conformal cooling channels’, providing soundest solution to the molds requiring high precision and longevity! In this application, GC Precision provides services as follows:

-

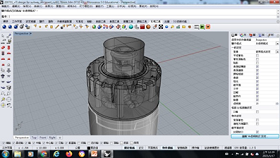

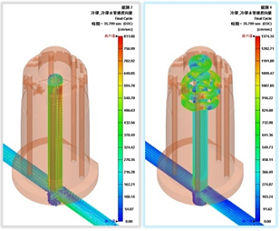

■ Design of conformal cooling channel ─ offering cooling channel design that cater to mold feature of metal die casting/plastic injection

-

■ Cooling channel performance analysis ─ specialized analysis is employed on the benefit from introducing conformal cooling channels to allow customers to understand the improvement

-

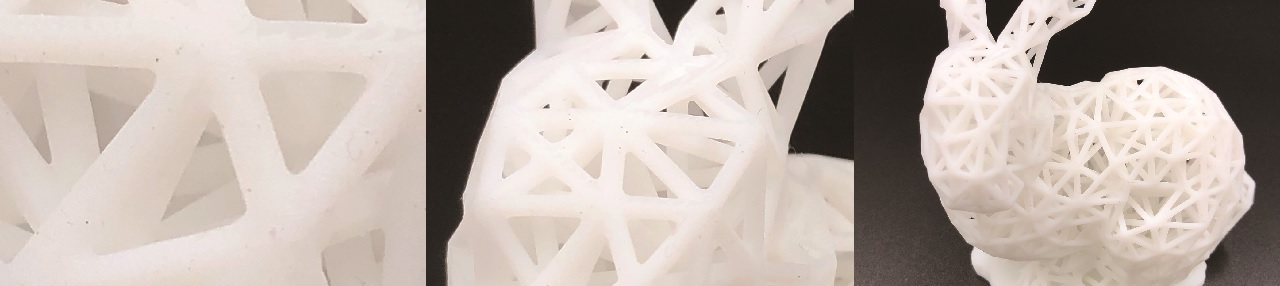

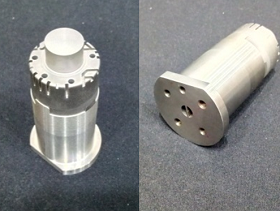

■ 3D printing making ─ capable of making complete products simply by 3D printing; or, employing grafting to reduce cost

-

■ cutting/EDM/CNC machining/coating can all be accomplished, offering ‘One-stop’ and complete manufacturing service, saving customers the trouble of dealing with multiple suppliers