Case study

Other parts/products

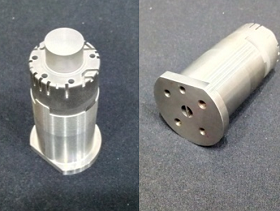

Out of the box of traditional processes that can deal with the “appearance” of workpiece only, metal additive manufacturing is capable of producing parts to correspond to special requirements (e.g., light weight and changes in structural strength). It provides breakthrough solution to the applications like aerospace, racing or high-speed mechanisms that require exceptional weight/strength ratio.

-

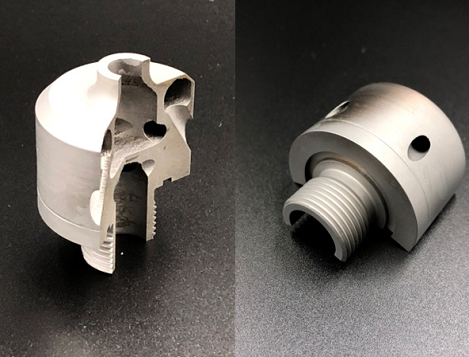

■ Nozzles/mold parts that are made by Hybrid methods. Parts of desired shapes are printed directed on the bases that were completed by CNC machining, maintaining the CNC precision requirement as well as the feature of complex shapes by additive manufacturing.

-

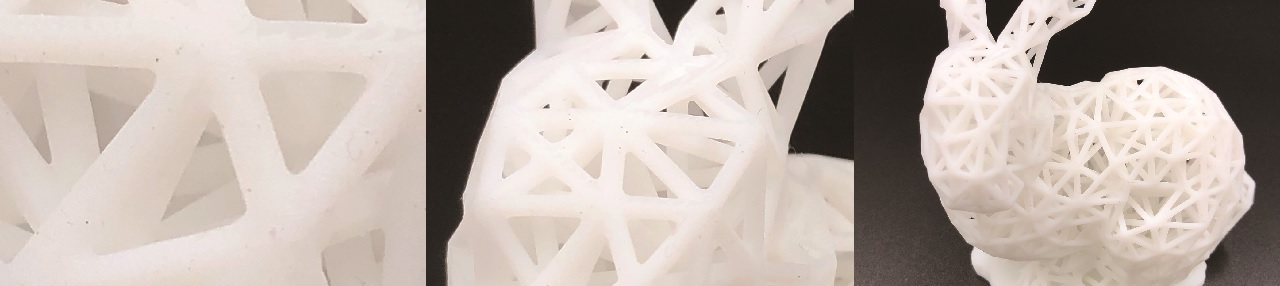

■ Parts with Lattice structure: these printed products can be put to use just after polishing

■Art work with inner lattice structure