Case study

Machining tools

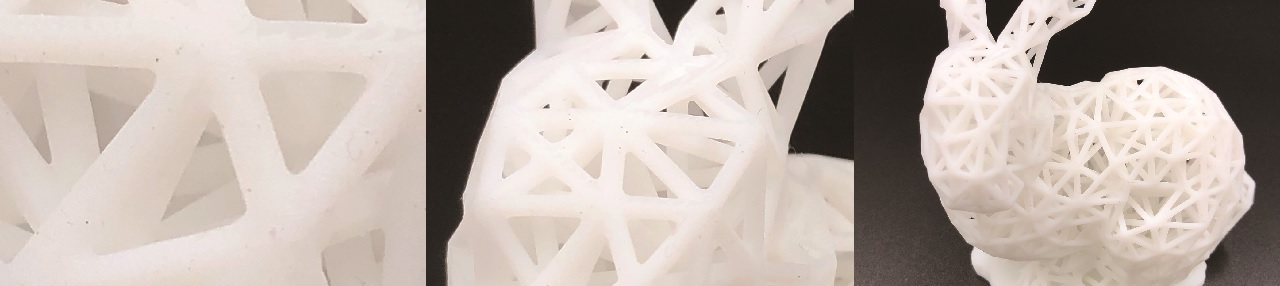

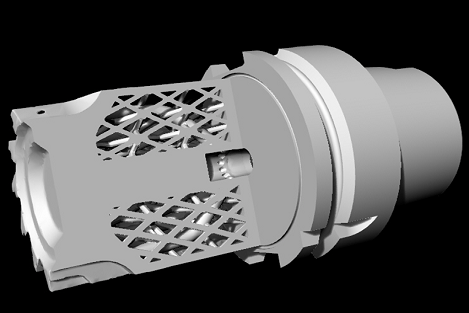

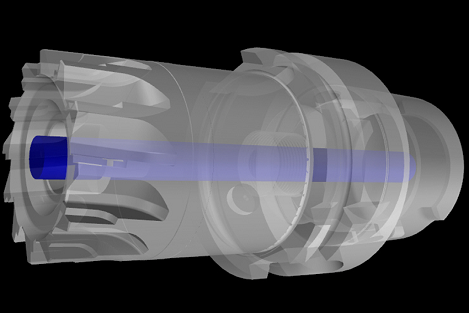

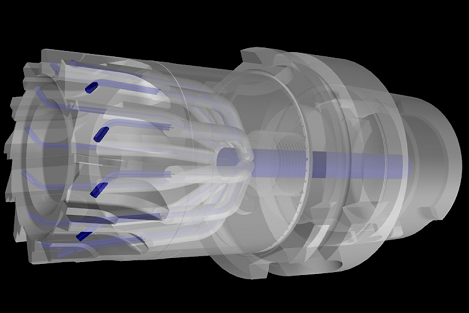

Metal additive manufacturing coupled with CNC machine center enables custom making of high-performance (high speed, high cooling effect/high efficiency) tools to meet customer’s demand in machining. Inner Lattice design can effectively reduce the weight of the tool, increasing machining efficiency as well as extending the service life of spindle. Special internal channel design also allows cutting fluid to shoot directly at tool tips, whereby to improve on machining quality and extend tool life.

-

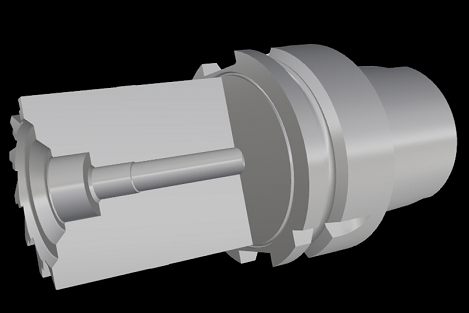

■ Conventional tool design: solid material, heavy

■ Design of inner Lattice less-weighted tools

-

■ Conventional design of tools with cooling channel (cutting fluid running off, unknown cooling effect)

■Optimized design of inner cooling channel (direct injection at tool tip)